Back to > Major Fruits | Minor Fruits | Underutilized Fruits

![]()

|

||

|

|

||

Harvesting:

In papaya fruit harvesting, generally, fruit may be picked when yellow colour covers 1/5 to 1/3 of the surface peel. Fruits are harvested manually depending on the size and age of the tree. But it is preferable to harvest the fruit late in the morning until early afternoon to reduce the latex flow. Normally harvested by hand (preferably with gloves) especially when the trees are still young and within reach. Tools that will be used in picking the fruit when the trees much taller:

Wooden or bamboo pole fitted with cutting instrument with a catching net at the end of harvesting pole. Hand picking can also be facilitated with the help of a ladder or sometimes with a “plumber’s” stool.

Post harvest and Packaging:

Handling papaya fruit post harvest is to prepare the fruits for market and also to preserve the fruits quality so it can present on market as it demands. The objectives of post harvest technology applications are to maintain quality in terms of appearance, texture, flavor and nutritive value, to maintain food safety and also to reduce losses along the supply chain (between harvest and consumption).

Physiological Post harvest Changes:

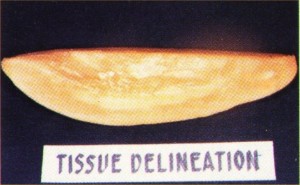

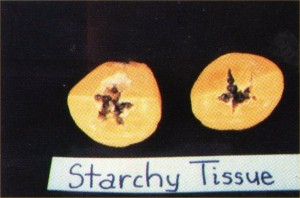

There were causes of physiological post harvest losses such as mechanical damages due to mishandling the fruits along the supply chain and loss of moisture through evaporation and transpiration. Beside that, death of tissues to interruption of metabolic rate when stored in the higher than optimum or extremely low temperature, shriveling effect and early senescence also the cause of this losses.

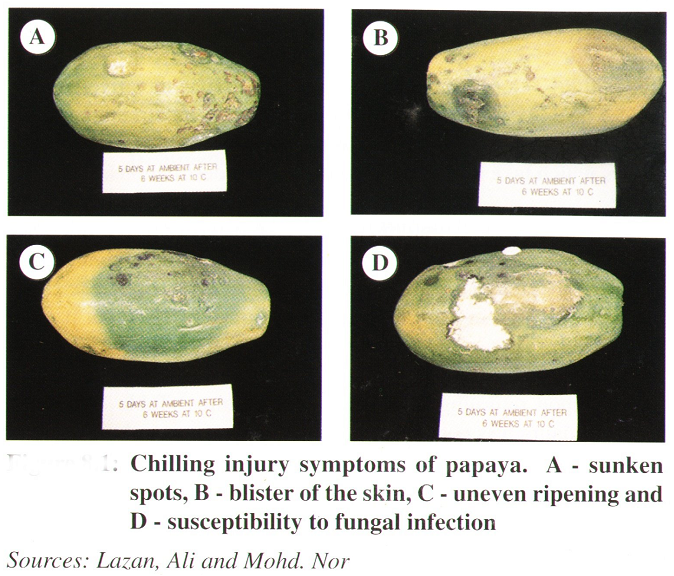

Chilling Injury (induced by exposing fruit to low but non-freezing temperatures).

Factors: cultivar, storage temperature duration of exposure, stage of ripeness, climate and soil factors.

Symptoms: uneven ripening, failure to ripen, skin discoloration, sunken spots and fungal blisters on the skin, susceptibility high to fungal infection and development of off flavor and odor.

Alleviation: important to reduce losses especially if the fruit are transported using refrigerated sea containers which take longer times to reach their destinations.

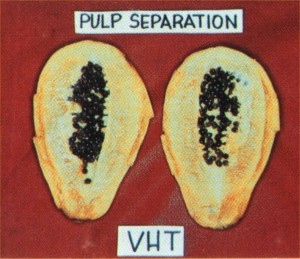

Hyperthemal Injury: occurs in papaya when exposed to heat.

Treatment: by using VHT (Vapor Heat Treatment), hot water treatment, high ambient temperatures.

Low shelf life: due to ethylene biosynthesis.

Spoilage and rot: due to invasion of pathogens on injured fruits.

|

|

|

Post harvest Treatment:

The uses of post harvest treatment as a safeguard against pest introduction into areas where they are not established. There were 2 commodities for the treatments, therefore chemical treatments like fumigation with volatile chemical and physical methods of treatments Double Hot Water Dip, VHT, Gamma Irradiation.

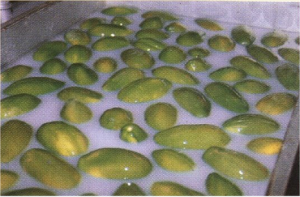

Double Hot Water Dip: The double dip method involves the treatment of less than quarter-ripe fruits for an initial immersion for 30 minutes in 107.6ûF (42ûC) water followed immediately by a second hot water immersion at 120.2ûF (49ûC) for 20 minutes.

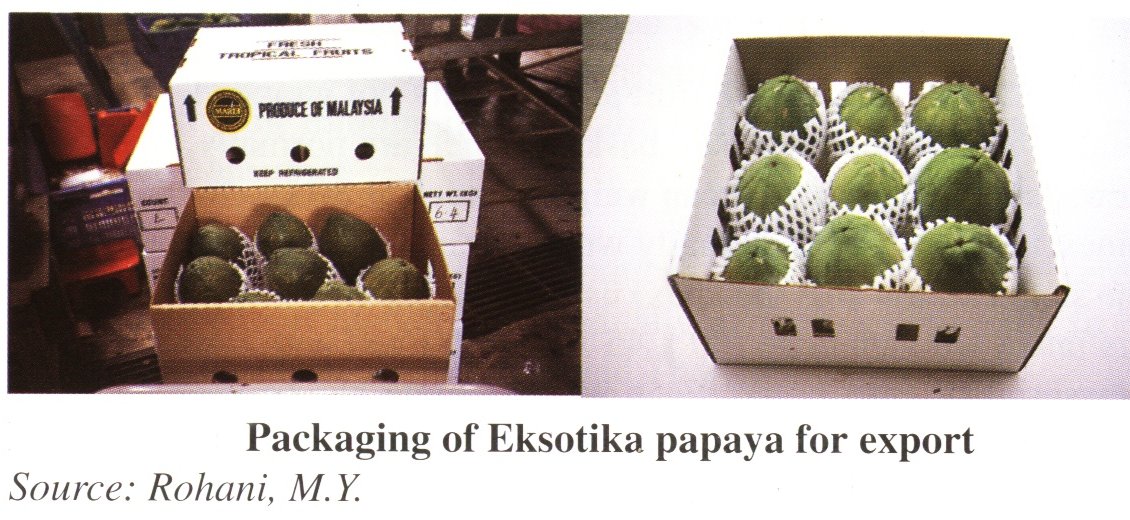

Packaging

There were two type of packaging: one for the export markets and secondly for local markets. For export markets, the fruits will be wrapped with white polyurethane sleeves, which serve as cushioning material preventing the fruits from bruising during transportation. Meanwhile, for local markets, the fruits are not wrapped. As a common practice the fruits were packed in bamboo or plastic baskets which are normally lined with newspapers.

But for Solo papaya, the fruits are wrapped individually with onion skin paper. They are packed in a single layer with the stem end facing down or packed in corrugated fiberboard cartons.

Processed Products

There were so many uses of papaya from ripe papaya until the seeds. For the ripe papaya, it is commonly eaten fresh and the flesh is often cubed or shaped into balls and served as a fruit salad or fruit cup. Besides that, firm ripe papaya may be seasoned and baked for consumption as a vegetable while firm ripe papaya. In Malaysia, half ripe papaya was sliced and crystallized as a sweetmeat or it called halwa betik.

Furthermore, this fruits also can produce a juice or nectar. As usual it can be sold as a fresh drink in bottles or can. InHawaii, the juice or nectar is reduced to puree with sucrose added to retard gelling. The puree is frozen for later use local. In mainlandUSA, fruit juice blending for making jam.

Papaya Chip |

Papaya Cosmetics & Toileteries |

Dried papaya |

Papaya Juice |

Pickled papaya |

Papaya Powder |

Air Refreshener |

Papaya Shampoo |

For the unripe papaya or green papaya, it was frequently boiled and served as a vegetable. InPuerto Ricocommonly canned in sugar syrup for local consumption and for export. In Queensland, green papaya must be checked for nitrate levels before canning. InVietnamandMalaysia, a popular dish using green papaya is “gỏi đu đủ bò khô” and “kerabu betik”, a salad like dish with shredded green papaya and shredded beef jerky eaten with a special hot sauce. Young leaves inEast Indies, cooked and eaten like spinach. The papaya seeds inIndia, sometimes found as an adulterant of whole black pepper.

Reference:

- Chong, S.T., R. Prabhakaran and H.K. Lee. ISHS Acta Horticulturae 787: International Workshop on Tropical and Subtropical Fruits.

- Lamberts, M. and J.H. Crane. 1990. Tropical fruits. p. 337-355. In: J. Janick and J.E. Simon (eds.), Advances in new crops. Timber Press,Portland,OR.

- Morton, J. 1987. Papaya. p. 336–346. In: Fruits of warm climates. Julia F. Morton,Miami,FL.

thank you for the information