Biodegradable ‘plastic’ bags made out of banana plants sounds a bit…bananas, but a couple of UNSW researchers have found a way to do it, and it could solve two industrial waste problems in one.

Two researchers at UNSW Sydney have discovered a novel way to turn banana plantation waste into packaging material that is not only biodegradable, but also recyclable.

Associate Professor Jayashree Arcot and Professor Martina Stenzel were looking for ways to convert agricultural waste into something that could value add to the industry it came from while potentially solving problems for another.

A good contender was the banana growing industry which, according to A/Prof Arcot, produces large amounts of organic waste, with only 12% of the plant being used (the fruit) while the rest is discarded after harvest.

“What makes the banana growing business particularly wasteful compared to other fruit crops is the fact that the plant dies after each harvest,” said A/Prof Arcot, UNSW School of Chemical Engineering.

“We were particularly interested in the pseudostems—basically the layered, fleshy trunk of the plant which is cut down after each harvest and mostly discarded on the field. Some of it is used for textiles, some as compost, but other than that, it’s a huge waste.”

A/Prof Arcot and Prof Stenzel (UNSW School of Chemistry) wondered whether the pseudostems would be valuable sources of cellulose—an important structural component of plant cell walls—that could be used in packaging, paper products, textiles and even medical applications such as wound healing and drug delivery.

Using a reliable supply of pseudostem material from banana plants grown at the Royal Botanic Garden Sydney, the duo set to work in extracting cellulose to test its suitability as a packaging alternative.

“The pseudostem is 90 percent water, so the solid material ends up reducing down to about 10%,” A/Prof Arcot said. “We bring the pseudostem into the lab and chop it into pieces, dry it at very low temperatures in a drying oven, and then mill it into a very fine powder.”

Prof Stenzel continued:

“We then take this powder and wash it with a very soft chemical treatment. This isolates what we call nano-cellulose which is a material of high value with a whole range of applications. One of those applications that interested us greatly was packaging, particularly single-use food packaging where so much ends up in landfill.”

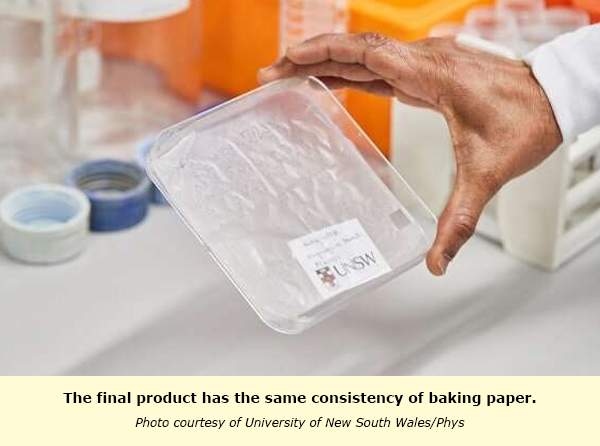

When processed, the material has a consistency similar to baking paper.

A/Prof Arcot said depending on the intended thickness, the material could be used in a number of different formats in food packaging.”There are some options at this point, we could make a shopping bag, for example,” she said.

“Or depending on how we pour the material and how thick we make it, we could make the trays that you see for meat and fruit. Except of course, instead of being foam, it is a material that is completely non-toxic, biodegradable and recyclable.”

A/Prof Arcot said she and Prof Stenzel have confirmed in tests that the material breaks down organically after putting ‘films’ of the cellulose material in soil for six months. The results showed that the sheets of cellulose were well on the way to disintegrating in the soil samples.

“The material is also recyclable. One of our Ph.D. students proved that we can recycle this for three times without any change in properties,” Professor Arcot said.

Tests with food have proved that it poses no contamination risks.

“We tested the material with food samples to see whether there was any leaching into the cells,” Professor Stenzel said. “We didn’t see any of that. I also tested it on mammalian cells, cancer cells, T-cells and it’s all non-toxic to them. So if the T-cells are happy—because they’re usually sensitive to anything that’s toxic—then it’s very benign.”

Source: Lachlan Gilbert, University of New South Wales/Phys.org